July 24, 2023

July 24, 2023

Industrial operations rely on the ability to read and record the weight of applications and their contents and understand mechanical force. Load cells are transducers that translate mechanical force into straightforward digital values. There are many different types of load cells, offering various benefits depending on the application. Massload Technologies is an expert industrial manufacturer providing a range of load cells, including shear beam, single beam, double beam, s-type, single point bending beam, pancake, column, donut ring, button, and canister varieties.

Load Cell Advantages

Precision force measurement is vital in industrial operations. Many electronic weighing scales use load cells because of their high level of accuracy.

Load Cell Types

Load cell types are determined by the kind of output signal generated or according to the way the weight is detected. Massload Technologies is an industry leader in strain gauge output signal load cell transducers. Depending on its operations, different types of load cells provide various advantages to meet application requirements; selecting a weight detection solution that appropriately reflects the application’s contents is essential. Strain gauge load cell transducers include shear beam load cells, bending beam load cells, and other types, offering different methods for force measurement.

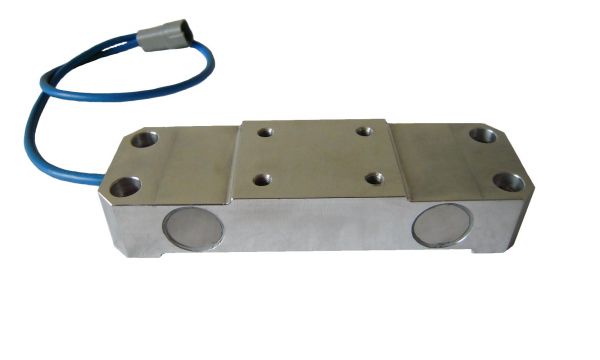

Shear Beam Load Cells vs. Bending Beam Load Cells

Shear beams and bending beams differ in how they measure force. In bending beam load cell solutions, force measurement is determined by placing the strain gauge on the surface of the load cell so that applied force causes the strain gauge to deform as the load cell bends. Shear beam load cells employ shear force measurement, indicated by objects sliding on one cross-section against another. An easy way to recognize shear beam load cells from bending beams is by a large hole bored partially through either side of the load cell, leaving a thin web in the center bonded to the strain gauge to sense the strain (shear) when the load is applied.

Single Beam Load Cells

A type of shear beam load cell, single beam cells use strain gauges near one end of the load cell to measure a single point of shear distortion for determining force stress measurement.

Single beam load cells are fixed on one end with the force applied at the other.

Double Beam Load Cells

Like single beam load cells, double beam cells measure weight by shear strain and come with two points where shear distortion can occur, offering a highly flexible weighing solution. Double beam load cells are fixed on both ends, with the load applied in the center of the load cell.

S-Type Beam Load Cells

Typically used in weighing applications under 50 lbs., s-type beam load cells are shear beams that apply force weight on the metal spring element, causing deformation, and measure weight by the fractional change in deformation. S-type beam load cells are ideal for small forces and are best suited for crane scales or tension applications.

Single Point Bending Beam Load Cells

These bending beam load cells are secured at one end, with the load applied to the opposite end. A standard bending beam solution, single-point bending beam load cells measure force by the distortion within the beam.

Pancake Load Cells

Characterized by their flat form, pancake load cells are strain gauge load cell types that can sense tension and compression forces. Pancake load cells offer precision through stability to their applications.

Column Load Cells

Designed with a spring element intended for axial loading, column load cells offer an ideal general testing solution. Usually, column load cells feature a minimum of four strain gauges, with two positioned to sense the strain’s tension for force measurement, and are considered lightweight for their application capabilities.

Donut Ring Load Cells

Offering high accuracy and stiffness, donut ring load cells are low-profile solutions with compression capabilities. They feature a through hole, making donut cells ideal for applications that require the load structure to pass through the sensor.

Button Load Cells

Recognizable as small load cells that are typically used in spacially limited applications, button load cells offer compact strain gauge-based sensors with a spherical radius.

Canister Load Cells

Like column load cells, canister load cells are cylindrical force measurement solutions that are used to measure compression and tension forces. They are designed for high capacity and engineered to withstand side forces and bending.

Find the Right Load Cell for Your Application with Assistance from Massload Technologies

Not sure which load cell type is right for your application? Contact us with any questions regarding load cell capabilities and offerings, or request a quote for a specific force measurement solution.