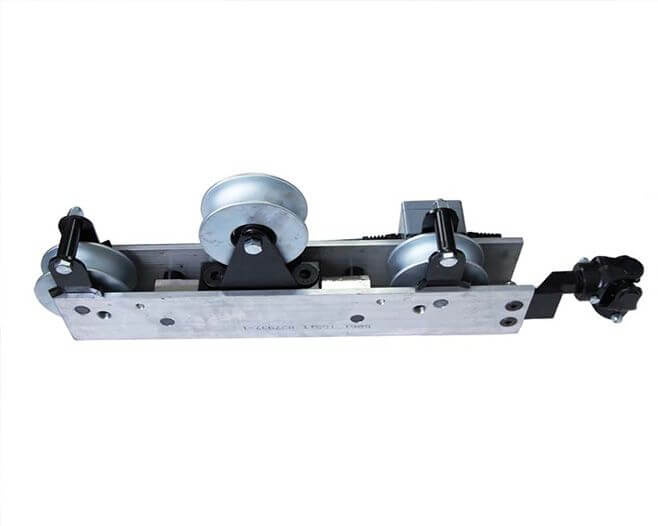

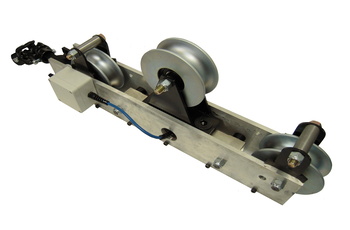

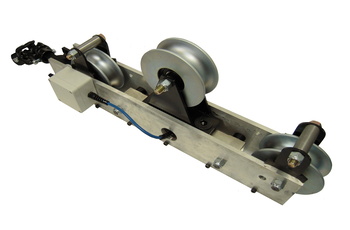

Floating Running Line Tensiometer

This Running Line Tensiometer is ideal for applications involving a moving wire rope of diameter 0.5 to 1.5in and a rope tension up to 100,000 lbs. The scale rides on the rope and determines cable tension by measuring the force of small deflections from its rollers. Common applications include crane boom, cable ferry, and line tension measurement.

Highlights

- This is a Running Line Tensiometer that allows wire rope to move through it without interference

- Used in tension applications where a dead end is not available for load measurement

- It does not use up crane head space

- Handles load capacities for wire rope sizes specified

- Digital display options

- Wireless options to hand held display, PC or 4-20mA PLC interface

Product Details

Running Line Tensiometer

If you have a wire rope with no dead end for load measurement, then the Running Line Tensiometer may be the answer. The Running Line Tensiometer rides on the rope via rollers and its roller configuration causes a slight deflection in the rope. As rope tension changes, the force applied to the load cell changes and weight data is displayed on a digital indicator. A properly installed Floater does not affect or interfere with spooling.

The Running Line Tensiometer arm is anchored at one end to a fixed, solid point (e.g., a boom). The anchor point locks the Running Line Tensiometer so it will not move with the wire rope and cause safety problems. Between the anchor point and the Running Line Tensiometer body is an arm equipped with two “U” joints. The “U” joints allow the Running Line Tensiometer to move freely in all directions and therefore does not affect wire rope spooling. This structure creates the ultimate in wire rope mobility and operator safety.

Although the Running Line Tensiometer converts rope tension to a weight display, the system should be considered a safety device rather than a scale. Accuracy can be dependent on many site specific factors so field calibration must be performed. Based on these considerations, the Running Line Tensiometer is often used in applications such as vehicle mounted cranes and stationary equipment “lifts” in mines. Models vary based on rope size:

- ½” to ¾” wire rope model

- ¾” to 1¼” wire rope model

- 1¼ to 1½” wire rope model

The Running Line Tensiometer is designed for rope tensions up to 100,000 lbs.

Images

PRODUCT SPECIFICATIONS

Please click on the following links to download or view additional information: