Weigh Modules for Tank and Hopper Weighing

Load cell weigh modules deliver exceptional performance for tank, bin, hopper, or vessel scales, as well as any application requiring legal-for-trade accuracy when the load is applied from above.

Massload Technologies is renowned for manufacturing high-quality weighing solutions, catering to various industrial needs.

Our weigh modules are essential for industries such as mining, oil and gas, OEM, agriculture, and cement/batching, where accurate weight measurement is critical to ensure safety, efficiency, and reliability.

What is a Weigh Module?

A weigh module is a weighing system that integrates several key components, including load cells, load transfer devices, and installation connectors.

This combination transforms non-traditional structures like hoppers, tanks, vessels, conveyors, and OEM machinery into functional scales.

Utilizing either tension or compression technology, weighing modules offer a versatile solution for converting various industrial elements into accurate weighing systems.

Request A Solution

Single Animal Scale Load Bars

Load beams are a good solution for cattle weighing. They consist of two beams that go widthwise (like axles on a car) underneath your platform and penning. Load beams are heavy duty electronic weigh scales available in capacites of 2,000 lbs, 5,000 lbs, or 10,000 lbs pounds. They are excellent livestock scales for do-it-yourself weigh platforms.

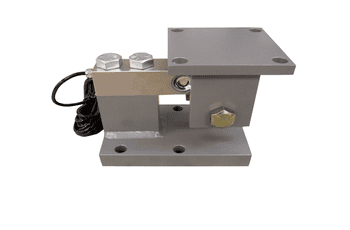

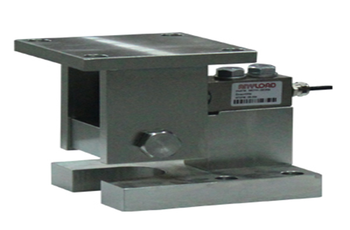

TWA-10010-5-10K LOAD CELL WEIGH MODULE

Support local manufacture with Massload's TWA10010 5,000 lbs Large Envelope and 10,000 lbs single-ended compression load cell weigh module for rugged and durable tank, hopper and vessel weighing

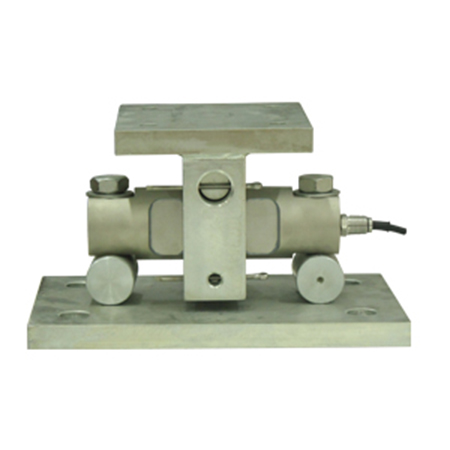

102DHM3-30-75K TANK LOAD CELL WEIGH MODULE

Anyload double-ended load cell weigh module for 5,000 lbs - 20,000 lbs and 30,000 lbs - 75,000 lbs load cell capacities.

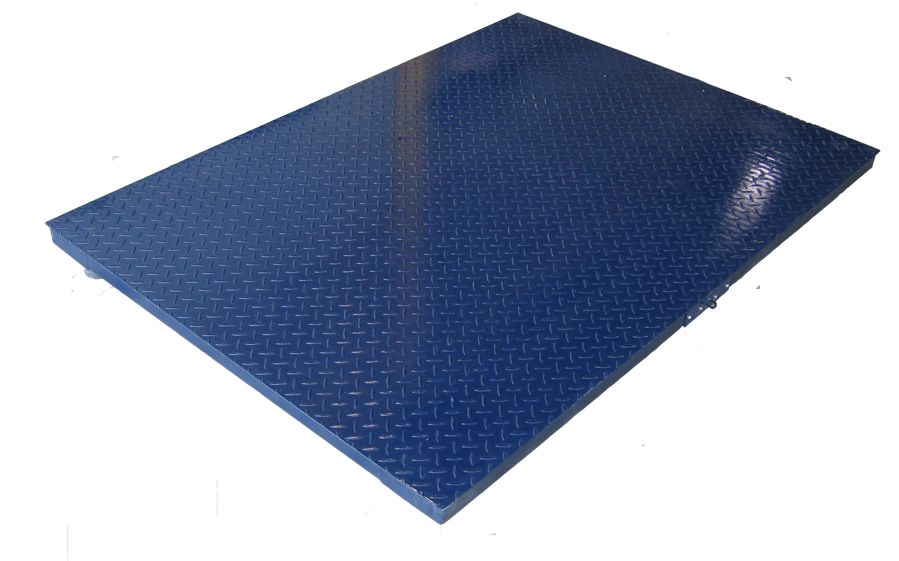

Floor Scales

This platform scale is an affordable low profile, industrial floor scale. Equipped with four ML-100 model single ended shear beam load cells, it is the affordable answer to your weighing needs. This scale is available in a range of sizes and capacities. The free floating foot is adjustable which allows you to level the scale to ensure maximum accuracy.

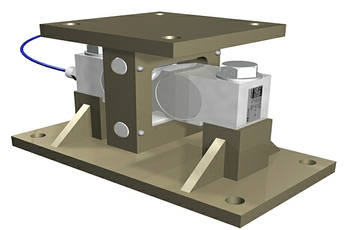

TWA-50025-125K LOAD CELL WEIGH MODULE

Support local manufacture with Massload's TWA50025K-75K double-ended load cell weigh modules for rugged and durable tank, hoper and vessel weighing.

563YHM2-1-5KSE LOAD CELL WEIGH MODULE

Anyload single-ended load cell weigh module for 1,000 lbs - 4,000 lbs and 5,000 lbs SE single-end load cell capacities.

V100000/10275 LOAD CELL WEIGH MODULE

Laumas V100000 weigh module pairs with Laumas CBL compression load cell for compact and accurate tank, hopper and vessel weighing.

Levelling Feet – Free Floating Feet

A levelling foot or free floating foot is the most common method of point loading a single ended load cell. These are threaded into the end of the load cell and used to transfer the weight to the ground.

What is the Difference Between a Load Cell and a Weigh Module?

A load cell is a single component that measures force or weight and converts it into an electrical signal.

It is typically used in traditional scales and is essential for obtaining precise weight measurements.

In contrast, a weigh module is a mechanical arrangement to precisely apply load to a specific type of load cell for most accurate and stable reading.

These extra elements are designed to protect the load cell and enhance its performance, ensuring accurate readings even in challenging conditions.

Essentially, while a load cell is the core measuring device, a weigh module is an integrated solution that can transform non-traditional structures like tanks, hoppers, and conveyors into fully functional scales.

Types of Weigh Modules

Massload Technologies offers various types of weigh modules, each designed to meet specific industrial needs:

- Compression Weigh Modules: Ideal for static loads in tanks and hoppers, providing high accuracy and reliability.

- Tension Weigh Modules: Suitable for applications requiring measurement of tensile forces.

- Single End Shear Beam or Double End Shear Beam Load Cells: Versatile modules used in multiple applications, offering robust performance and durability.

Weigh Module Applications

Tank Weighing Solutions

Accurate tank weighing is vital in many industries. Massload Technologies’ weigh modules provide reliable and precise measurements, ensuring optimal process control and inventory management.

Key features include:

- High Precision: Ensures accurate weight readings for precise process control.

- Durability:Designed to withstand harsh industrial environments.

- Ease of Integration: Simple installation and maintenance reduce downtime.

Hopper Weighing Solutions

Weigh modules guarantee consistent and accurate weight measurements, enhancing operational efficiency.

Key benefits include:

- Reliability: Consistent performance in various environmental conditions.

- Robust Construction: Built to endure tough industrial settings.

- Accurate Measurements: Ensures precise material handling and processing.

Weigh Modules for the OEM Industry

The Original Equipment Manufacturer (OEM) industry requires reliable and customizable weighing solutions for diverse applications. Massload Technologies’ weigh modules can be seamlessly integrated into OEM equipment, providing:

- Improved Accuracy: Our weigh modules enhance the performance of OEM equipment by providing precise measurements.

- Reliability: Consistent and dependable weight measurements from our weigh systems ensure that OEM equipment operates smoothly and efficiently.

- Customization Options: Tailored solutions to meet specific customer requirements, including load capacity, material, and environmental protection.

Installation and Maintenance

Proper installation and maintenance are crucial for the optimal performance of weigh modules.

Here are some tips:

- Installation: Ensure a stable and level foundation to prevent measurement errors. Follow the manufacturer’s guidelines for mounting and alignment.

- Maintenance: Regularly inspect the weighing modules for signs of wear and tear. Calibrate the load cell that pairs with the module once a year to maintain accuracy. Protect the modules from extreme environmental conditions to prolong their lifespan.

Massload’s Custom Design Weigh Module Options

Massload Technologies specialises in rigid mount load cells that achieve accuracy similar to load cells in weigh modules but with a much lower profile resulting in more compact and significantly less expensive OEM designs.

Whether you require specific load capacities, materials, or environmental protection, we can tailor our weigh systems to your exact specifications.

To know more about our custom design process, read: What’s Involved in the Design and Engineering Process for Custom Load Cells?

Hopper On Board with Massload Technologies Weigh Modules Precision

Choosing Massload Technologies for your tank and hopper weighing needs guarantees accuracy, reliability, and tailored solutions.

Ready to enhance your weighing accuracy? Fill out the form below to request a quote or contact us directly.