Custom Load Cell Transducers

Massload specializes in designing and manufacturing custom load cell transducers in Canada and the United States. If you have an application and cannot find a suitable load cell, our engineering team will work with you to get you the information you need and develop a load cell that will meet your requirements.

Highlights

- Custom load cells provide versatility for any load application

- Custom designed and engineered to meet specific capacity, overload, and loading requirements

Features

- Engineered to your specific capacity

- Sized to meet your load and support application

- Safe overload capacity typically 150% FS

- Ultimate overload capacity typical 400% FS, up to SF 10:1 for safety critical applications

- Temperature compensated

- Materials are 4340 or 17-4 PH stainless steel

- All material sourced from quality mills in USA or Europe

- Surface finish: Electro-less nickel or electro-polished stainless steel

- Output options include mV/V, 4-20 mA, 0-10V, wireless, and more

Design Process

- We start by discussing your weighing application. Typically our engineers will work with your management and/or engineers to identify the optimal load cell design

- A price estimate is then provided

- When you are ready to proceed, we typically request a deposit on the order

- Upon receipt of the deposit, we engineer the load cell and provide you with engineered approval drawings for final approval

- When drawings are approved, detailed engineering and manufacturing commences

- Lead time is subject to material availability and production loading, but is typically quite fast.

Product Details

Custom Load Cell Transducers

What sets custom load cell transducers apart is their tailored design and engineering to suit specific requirements of diverse industries.

Crafted with meticulous attention to detail, our team collaborates closely with clients to develop bespoke load cell solutions that precisely match unique application requirements.

From specific capacity engineering to diverse output options, our custom load cells offer versatility, durability, and accuracy.

Engineered to exceed expectations, these transducers stand as a testament to our commitment to delivering tailored solutions for every weighing application.

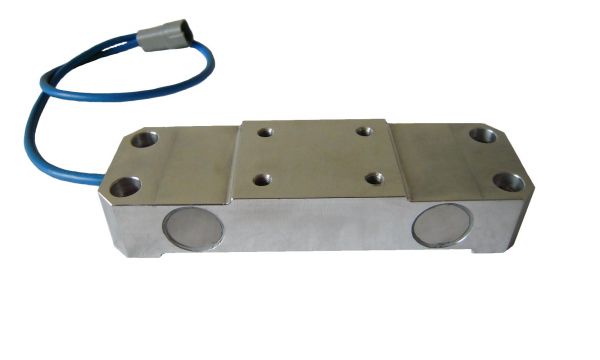

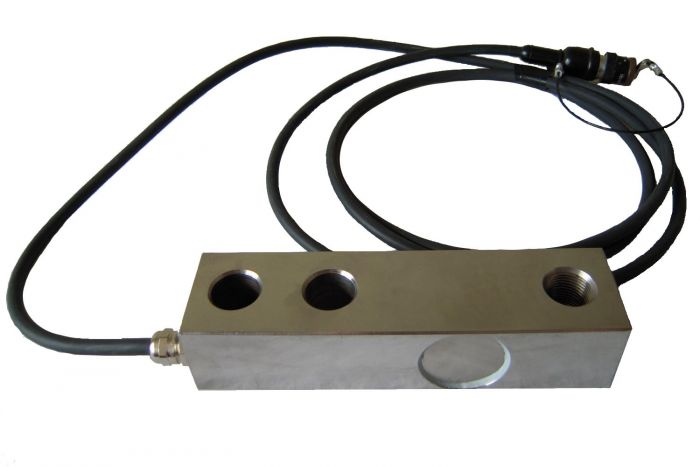

Images

PRODUCT SPECIFICATIONS

Frequently Asked Questions About Custom Load Cells

How do load cell sensors work?

Load cell sensors convert a mechanical force into an electrical signal. When a force is applied to the load cell, it causes a deformation in the strain gauge material, which changes its electrical resistance. This change in resistance is measured and converted into a readable output, providing precise measurement of the applied force.

Will you be measuring bending, tension or compression?

At Massload Technologies, we design custom load cells that can measure bending, tension, compression, or multi-axis forces. Our engineering team works with you to identify the specific requirements of your application to ensure the load cell is tailored to measure the necessary parameters accurately.

How to choose the correct load cell and compatible electronic instrumentation for your load or force measurement application?

Choosing the correct load cell involves understanding your application’s specific needs, including the type of force, the range of load, environmental conditions, and required accuracy. Our team will guide you through selecting the appropriate load cell and compatible electronic instrumentation, considering factors like load capacity, size, material, and output requirements to ensure optimal performance and reliability.

What are the differences between compression, tension, and multi-axis load cells?

Compression load cells are designed to measure force in one direction, pushing together, while tension load cells measure force in the opposite direction, pulling apart. Multi-axis load cells can measure forces and moments in multiple directions (usually two orthogonal directions) simultaneously, providing a comprehensive view of the forces at play. Each type is engineered for specific applications and load conditions

What is the maximum load, weight or force you intend to measure?

The maximum load that our load cells can measure varies widely, depending on the custom design and specifications of each unit. We design load cells to meet the specific maximum load requirements of your application, ensuring accuracy and adequate factors of safety without compromising performance.

What is the difference between a load cell and a strain gauge?

A strain gauge is a component that measures the deformation (strain) of an object when a force is applied. A load cell, on the other hand, is a device that includes strain gauges among other components and is designed to measure force or load. The strain gauges within the load cell provide the electrical change needed to calculate the force applied to the load cell.

What is the temperature range of Massload load cells? / What is the temperature range for operation?

The operating temperature range of our load cells can vary depending on the specific model and application. Generally, our load cells are designed to operate effectively within the typical industrial temperature ranges. We can also design load cells for extreme temperature conditions based on your specific needs.

What is load cell sensitivity?

Load cell sensitivity refers to the output signal change per unit of change in the measured force. It is typically expressed in millivolts per volt (mV/V) of excitation at full scale. High sensitivity means the load cell can detect smaller changes in force. Our engineering team ensures that each load cell is designed with the appropriate sensitivity level to provide accurate and reliable measurements for your application.

How does Massload design a load cell to meet your needs?

Our design process begins with a detailed discussion about your application’s specific requirements. We consider factors like load type, capacity, factors of safety, accuracy and environmental protection.

Following this, we provide engineered drawings for approval and proceed with the manufacturing of a load cell that meets your exact specifications, ensuring it fits seamlessly into your application.