Truck Axle Scales for Multiple Applications

An accurate, durable, and portable truck scale is essential for monitoring loads, avoiding overloading, and preventing premature mechanical failure. Massload Technologies manufactures a range of high-quality mobile axle pad scales for trucks, underground mining vehicles, underground utility vehicles, and industrial load weighing applications. We offer factory calibrated Canadian-made truck axle scales featuring auto-weigh, dual tire weigh surfaces, and application-specific features. Massload’s hand portable Ultraslim wheel load scales and portable weigh-in-motion scales are designed for check weighing and traffic enforcement. Our available selection of industrial weigh scale systems includes load cells, strain gauge load cells, digital truck scale indicators, amplifiers, and other components required for efficient and accurate truck load weighing.

View the benefits and applications of a Portable Truck Axle Scale system from Massload below, request help from one of our Experts, or send us an email here. Let us find a solution for your vehicles or trailer weighing needs.

Request A Solution

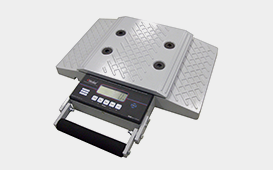

Axle Pad Scales

These rugged, accurate, easy-to-use axle pad scales feature auto weigh, which provides a single user with the truck weight in seconds. Built with our high quality Canadian made load cells on a rugged steel platform and calibrated with certified weights.

Farm Truck Scales

Rugged, reliable and economic. Massload's Axle Pad Farm Scales help you optimize your farm through input weighing, air drill and combine yield monitor calibration, and outbound overload fine prevention. Farm truck scales are designed to weigh Large Super B Train Trucks and ag equipment. Wired and wireless options are available.

Ultraslim Portable Vehicle Weight Scales

Our extremely popular low profile Ultraslim wheel load scale has a dual tire weigh surface and our large LCD display making it a very portable and easy-to-use wheel weigher. With weigh pad capacities up to 40,000 lbs, it provides an economical truck axle scale for Tandems, Tri-Axle Trailer, Super-B Trains, Ag Equipment, Law Enforcement Vehicles & more.

Mining Vehicle Scales

These large, heavy duty axle pad scales are ideal for mining truck weight checking and calibration of truck scales and loader scales to ensure optimized loading and operational throughput.

Standard Wheel Load Scales

These light weight yet rugged wheel load scales are ideal for wheel weighing on the go. Built with our high quality Canadian made load cells in a heavy duty cast aluminum body and our highly accurate LCD display providing a cost effective truck scale. We regret this model is currently unavailable while we resolve supply chain issues.

Trailer Loading Dock Scales

Massload's range of configurable axle pad scales provide heavy duty, reliable and easy to use solutions for any truck trailer loading setup. These scales offer a large weighing surface and can accommodate dual axle truck weighing and tri-axle truck trailer weighing.

Axle Pad Scales

These calibrated vehicle scales feature a large weighing surface and low 6” profile, making for the easiest and most efficient methods for determining truck axle weight. Axle pad scale systems can be used with ramps for above ground installations or flush with concrete for a pit-installed permanent application. Highlights include Axle weight accurate to within 0.25% FS and Gross vehicle weight (Super-B) accurate to within 1% FS.

Axle Pad Applications

- Large Vehicles

- Trucks

- Tankers

- Trailers

- Heavy Duty Equipment

Farm Truck Scales

The rugged, reliable Massload Farm Scale™ is designed for easy installation and use directly on farm yard compacted gravel or on a concrete pad. Highlights include real-time data management with Truck-in / Truck-out capability and in-ground Weigh-in-Motion systems for touch free operation.

Farm Truck Scale Applications

- Large Super-B Train Trucks

- Ag Equipment

Mining Vehicle Scales

Massload’s easy to use High Capacity Truck Scales and Advanced Weigh Scale Software provide loader calibration, overload protection, and load optimization. Mining vehicle scale features include Axle weight accumulation and totalization, Truck ID capture before or after weigh, Truck-in / Truck-out, and Data logging for operational analysis.

Mining Applications

- Surface and Underground Mining Vehicle Fleets

- Mining Utility Vehicles

Trailer Loading Dock Scales

Trailer loading axle pads are IP-66: totally protected from dust and strong jets of water for improved longevity. These scales offer individual axle weight tested to an accuracy of 0.25% FS nominal.

Ultraslim Portable Vehicle Weight Scales

Our Ultraslim wheel load scales are extremely low profile, portable, and come with two attachable ramps for static weighing. Additional options include a built-in LCD display, built-in wireless, and a military quick disconnect cable.

Ultraslim Scale Applications

- Tandem

- Tri-Axle Trailer

- Super-B Trains

- Ag Equipment

- Law Enforcement Vehicles

Truck Axle Scales For Various Industries

Our team of experts understands the industry regulations and requirements for accurate weighing systems. We have experience providing accurate truck scales to industries requiring rugged, heavy-duty weighing solutions.

Portable Truck Scales by Industry

- Mining Weighing Scales

- Truck Weighing Scales

- Traffic Enforcement Weighing Scales

- Trailer Weighing Scales

- Agriculture Weighing Scales

Contact Massload For a Custom Portable Truck Axle Scale System in Canada and the United States

We are confident we have a portable truck scale system for your application in North America. Contact Us online to learn more about our features and available offerings, or Request a Solution and let us find the truck axle scales you need.

Frequently Asked Questions

How Are Truck Axle Scales Used?

Our Scales Are Used For:

Compliance: So you don’t get fined for overloading.

Safety: To make sure the weight is evenly distributed across all axles avoiding accidents caused from uneven loads.

Maintenance: To reduce wear on the axle, tires, and road surfaces.

Efficiency: Optimizing the load helps to save on fuel and prevent wear on the truck.

Operators drive the truck over the axle scale slowly so each axle can be weighed individually. Some systems can weigh the truck in motion, others require the truck to stop for each axle to be weighed.

How Does a Truck Scale Work?

A truck scale works by using load cells, which are sensors for the measurement of pressure or force. When a truck drives onto the scale platform, the load cells under the platform measure the weight of the truck and convert that pressure into an electrical signal. The signal is then processed by the scale’s computer to calculate the total weight of the truck.

Most truck axle scales, except ultraslims, can handle very heavy loads, up to 100,000 pounds or more, which is the typical maximum weight for trucks on many roads. They can be above ground with ramps leading up to the platform or pit-mounted where the scale is level with the ground for easy access. The scale displays the weight on a digital or analog readout so you can record and manage weight data.

These types of scales are essential in logistics, construction, agriculture, and any industry that transports heavy goods to make sure vehicles are safe and legal for public roads.

Do Truck Scales Weigh Each Axle?

Yes, truck scales can weigh each axle of a truck individually. This type of scale is called an axle scale and allows you to measure the weight on each axle to make sure the load is properly distributed and complies with weight limits.

Portable truck axle scales and permanent scales are critical to prevent overloading which can result in fines and wear and tear on the roadways.

Are They Accurate?

A portable truck scale is engineered to provide very accurate measurements for business operations, compliance and safety. The accuracy is usually within 0.1% to 0.25% of the actual weight depending on the scale design and quality. Factors that affect their accuracy are:

Calibration: Calibration is crucial to maintain accuracy. Portable scales must be calibrated when installed, moved, or after any impact or change to the weighing surface. We recommend that scales be recalibrated once a year.

Maintenance: Proper maintenance prevents issues that can affect accuracy such as debris buildup, wear and tear on load cells and corrosion.

Environmental Conditions: Temperature fluctuations, humidity, and vibrations can affect the scale’s accuracy. High-quality portable truck scales are designed to minimize these effects.

Surface and Installation: The surface a portable scale is placed on must be stable and level. Even small inclines or instability can cause inaccuracies.

Legal-for-trade: Although our truck scales are very accurate, they are not legal-for-trade. For commercial use a weighbridge scale is required.

How Do They Function?

Portable truck scales use a system of load cells which are the heart of the weighing process. Here’s a more detailed explanation:

Load Cells: These are transducers that convert a mechanical force into an electrical signal. When a truck is on the scale, the load cells are compressed and that compression is converted into an electrical signal proportional to the force applied.

Signal Processing: The electrical signal from each load cell is sent to a junction box which combines the signals. That combined signal is then sent to a digital indicator or computer system that processes and converts it into a weight reading.

Portability: These scales are designed to be easy to transport and set up. They come in modules that can be connected to form the full scale. Portability doesn’t compromise durability – high quality models are built to withstand heavy use and various weather conditions.

Usage: Operators can set up these scales on different sites and are ideal for industries that need weighing capabilities in multiple locations. They are used in construction, agriculture, waste management and logistics.