APX PROGRAMMABLE DIGITAL LOAD CELL INDICATOR

The “APEX” of accuracy and process control, APX programmable indicators deliver the highest level of performance for all types of weighing applications. Up to 4 weighing channels may be viewed on the bright and adaptive 5.6 inch color display while the modular concept permits endless connectivity and systems integration options. Technician-friendly features such as menu driven configuration, backup solutions and on-screen diagnostics & monitoring make the APX easy to install, set-up and calibrate.

The APX introduces scale-based process automation using real-time function calls for optimum speed. Each APX can be spec’d for a specific application with the ability to add-on an ever-growing list of network options. Programs may vary in complexity with custom messages, graphics, interfaces and reporting suitable for everything from basic weighing transactions to weight-based control systems. Data such as Tare IDs, PLUs, Recipes and Ticket/Label formats may be stored in a variety of memory formats or uploaded to PCs and ERP systems.

Highlights

- Programmable indicator for process control

- Scale-based process automation

- Highest accuracy

- Up to 4 weighing channels

- Real-time function calls

- Bright and adaptive 5.6 inch color display

- Menu driven configuration

- On-screen diagnostics & monitoring

Product Details

APX PROGRAMMABLE DIGITAL LOAD CELL INDICATOR

The APX sets a new benchmark in precision and process control, delivering unparalleled accuracy across diverse weighing applications.

Offering the ability to monitor up to four weighing channels simultaneously on a vibrant 5.6-inch color display, coupled with extensive connectivity options and user-friendly features, the APX ensures ease of installation, setup, and calibration.

Experience scale-based process automation at its finest with real-time function calls that optimize operational speed.

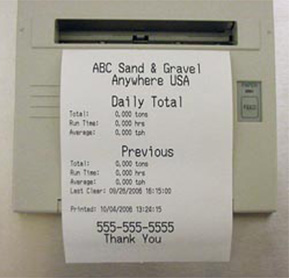

The APX introduces scale-based process automation using real-time function calls for optimum speed. Each APX can be spec’d for a specific application with the ability to add-on an ever-growing list of network options. Programs may vary in complexity with custom messages, graphics, interfaces and reporting suitable for everything from basic weighing transactions to weight-based control systems. Data such as Tare IDs, PLUs, Recipes and Ticket/Label formats may be stored in a variety of memory formats or uploaded to PCs and ERP systems.

Images

PRODUCT SPECIFICATIONS

Please click on the following links to download or view additional information:

- Brochure: Western Scale APX Indicator