Load Cells and Force Sensors

Massload Technologies designs and manufactures high-quality industrial grade strain gauges for truck, crane, mining, oil and gas, and industrial applications.

What is a Load Cell? Benefits & Applications

A load cell is a transducer that converts weight into electrical signals. When you put a load on the platform the load sensor detects the pressure exerted by the force.

Strain Gauge Load Cells and the Wheatstone Bridge

The commonly used strain gauge load cell works by measuring the small deflection in the load cell that causes the resistance in the strain gauge to change and produces an electrical signal in the Wheatstone Bridge circuit that is proportional to the weight.

This involves activating sensors and converting physical pressure into electronic data.

Need a Custom Load Cell for a Specific Use Case?

Our load cells come in many forms, each designed for specific applications and measuring different types of loads. We also offer custom load cells made for specific functions. The performance of this component can impact everything from safety and quality control to regulatory compliance and cost control.

Request A Solution

Custom Load Pin Transducers

Load Pins typically replace the clevis or sheave pin in a lifting or supporting device. They are ideal when head room is limited. As a safe load indicator, our Custom Load pins are professionally engineered and stamped based on your exact technical requirements. Support local manufacture with Massload's Custom Load Pins, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Options include cabled and wireless, mV/V, 4-20mA, 0-10V, 0-5V, +/- 10V. Common applications include clevis pins for mine workstage galloways, hoist rope attachments, crane modernizations, material handling and paper mills.

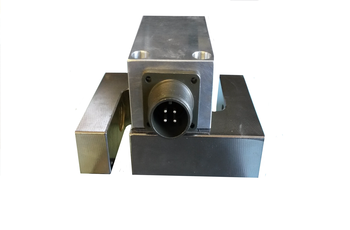

Custom Load Cell Transducers

Massload specializes in the design and manufacture of custom load cells made with the highest quality materials and manufactured through our VCAP Quality Management System. They are professionally engineered based on your particular technical requirements

Custom Tension Load Cell Transducers

Support local manufacture with Massload's Custom Tension Links, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. They are professionally engineered and stamped based on your exact technical requirements. Options include cabled and wireless, mV/V, 4-20mA, 0-10V, 0-5V, +/- 10V. Common applications include mine workstage galloways, hoist rope attachments and crane modernizations.

Tension Load Cells

Support local manufacture with Massload's rugged and reliable industrial grade ML-700 Tension Link model ranges from 10,000 lbs to 250,000 lbs, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Output options include cabled, wireless, 4-20mA, 0-10V, 0-5V, +/- 10V. Common applications include load lifting, and line tension measurement.

400 Double-Ended Shear Beam Load Cell Transducer

Massload's ML-400 double-end truck scale load cell model ranges from 50,000 lbs SE to 125,000 lbs LE, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. We also supply a full range of equivalent imported load cells

100 Single-Ended Shear Beam Load Cell Transducer

Support local manufacture with Massload's ML-100 single-end load cell model offered to OEMs ranges from 1,000 lbs to 20,000 lbs, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Output options include cabled, mV/V, 4-20mA, 0-10V, 0-5V, +/- 10V, and wireless . We also supply an wide range of single-end imported load cells. Common applications include tank, hopper, and vessel weighing.

200 S-Type Tension Compression Load Cell Transducer

Massload offers a high quality industrial grade S-type load cell of 10,000 lbs capacity with quick disconnect box for oilfield applications. We also supply a full range of S-type imported load cells for applications such as tank and hopper weighing.

Load Shackle – Load Pin Shackle

Support local manufacture with Massload's rugged and reliable industrial grade Wireless Load Shackle model with capacities from 8.5t, 12t, 17t, 25t, 35t, and higher. These are made from the highest quality materials including 17-4 Stainless Steel load pin and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Output options include cabled, wireless, 4-20mA, 0-10V, 0-5V, +/- 10V. Common applications include rigging, load lifting, and line tension measurement.

500 Double-Ended Shear Beam Load Cell Transducer

Massload's ML-500 double-end tank and hopper load cell model ranges from 25,000 lbs to 125,000 lbs, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. We also supply a full range of equivalent imported load cells.

600 Low Profile Double-Ended Shear Beam Load Cell Transducer

Support local manufacture with Massload's ML-600 low profile double-end load cell model in 5,000 lbs and 10,000 lbs capacity, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Typical applications include tank, hopper and batch processing.

HCH WAGON HITCH SINGLE-ENDED SHEAR BEAM LOAD CELL

Support local manufacture with Massload's rugged industrial grade ML-HCH single-end load cell model in 10,000 lbs and 17,600 lbs capacity. Made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Common applications include hitch and pintle hitch for grain cart and manure wagon.

1200 Double-Ended Shear Beam Load Cell Transducer

Support local manufacture with Massload's rugged industrial grade ML-1200 double-end load cell model in 25,000 lbs, 35,000 lbs and 75,000 lbs capacity. Made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Common applications include grain cart, tank, hopper and batch processing.

2000 Double-Ended Shear Beam Load Cell Transducer

Support local manufacture with Massload's rugged industrial grade ML-2000 double-end load cell model in 150,000 lbs capacity. Made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Common applications include oilfield proppant tank weighing and mining vehicle axle scales.

CBL TANK HOPPER LOAD CELL

The versatile low profile Laumas CBL compression load cell is ideal for tank, hopper and vessel weighing.

1100 Double-Ended Shear Beam Load Cell Transducer

Support local manufacture with Massload's rugged industrial grade Axle Pad Scale ML-1100 double-end load cell model in 25,000 lbs and 50,000 lbs capacity. Made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Common applications include on-farm Super B-Train truck weighing, industrial truck weighing, truck trailer loading and boat building.

What are the Applications of Load Cells in Various Industries?

One common attribute across load cell applications in many industries is precision. These compact electronics are essential for many business operations.

From improving safety by preventing cargo overload to precise measurements in commercial or manufacturing processes, load sensors can address many challenges across many applications and setups.

Load Cell Types

Load cells come in many forms, each designed to measure force or weight in specific conditions. Here’s a breakdown of the most common:

Load Cell Categories

- Strain Gauge

- Pneumatic

- Hydraulic

- Capacitive

Strain Gauge Load Cells

Strain gauge load cells use a sensing element that changes electrical resistance when stressed or deformed.

- This resistance change is directly proportional to the applied force

- Because of their linear resistance, strain gauge load cells can convert force into electrical signals for real-time monitoring.

Pneumatic Load Cells

Pneumatic load cells measure force using controlled air pressure, utilizing several key components:

- An air supply to provide a regulated airflow.

- A flexible diaphragm or bellows that deforms with applied load.

- Nozzle and flapper system that adjusts airflow based on diaphragm movement.

- Pressure gauge or transducer that converts air pressure into an electrical output signal.

- This allows for adjustment to measure different forces or weights. The pressure can be read through an analog gauge or as an electronic signal for digital processing.

Hydraulic Load Cells

Hydraulic load cells convert force into hydraulic pressure within a closed system.

- A piston and cylinder mechanism filled with hydraulic fluid compresses under weight or force.

- The applied force is proportional to the increase in hydraulic pressure.

- A pressure sensor or transducer converts the pressure into an electrical signal for processing and can be displayed as a digital value to the user.

This design is rugged for heavy-duty force measurement applications.

Capacitive Load Cells

Capacitive load cells detect changes in capacitance, a property that measures the ability to store electrical charge.

- These sensors have two parallel conductive plates separated by a gap, with voltage applied across them.

- When a load is applied, the plates move together, changing the gap and thus the capacitance.

- This change in capacitance, proportional to the applied force, is converted into an output signal through integrated electronics.

Capacitive load cells are suitable for high sensitivity and precise force measurement applications.

Each of these load cell types offers unique advantages, making them suitable for a wide range of industries and applications, from industrial manufacturing to scientific research.

Key Features and Capabilities of Massload’s Load Cells and Force Sensors

High-Precision

Our high-precision load cells are designed with the latest technology to give you the best force measurement.

When calibrated through a multi-point system they can give you a system accuracy range of 0.1% to 0.2%.

Durability and Robustness

Our load cells are made locally with attention to detail, with high level selected materials. The production team is always learning and improving.

The whole process is controlled to ensure we only give the best to our customers.

Compatibility

Our load cells work with many weighing setups, including other Massload Technologies accessories, making them suitable for many industrial applications.

If our standard products don’t fit your application we can always discuss custom design solutions.

Environmental Resistance

Our load sensors are built to withstand tough conditions, for outdoor and industrial use. They work in mines, harsh weather environments, and many other situations.

Customizable Load Cells

Load cells are not a one size fits all solution. That’s where our custom-made load cells and load pins come into play. Our engineers don’t just design them – they build them with each project’s unique needs in mind.

Custom-made solutions are approved and made with the best materials and technology. Contact us with your specs and enquire. We will work with you to get everything right.

Get to know some of our Case Studies:

Weigh Solution for Oil & Gas OEM: Natural Gas Desander

Grain Cart Custom Load Cells

What Industries Rely on Load Cells?

Ever wonder “What are load cells used for?” Here are a couple of industries where our products are well represented:

Agriculture

Our Farm Truck Scales are a weighing system that is ready to go use on purchase. But our agricultural applications for load cells go way beyond truck axle scales. They bring precision to crop yield measurement, manure spreading, hay compressors, grain bin management and more.

Discover more about how our solutions can transform your agricultural practices

Original Equipment Manufacturer (OEM)

In the OEM world load cells are a key part of the production line. They increase the precision and safety of the original equipment so manufacturers can trust their designs to perform as expected.

We partner with OEMs beyond just supplying parts; we create solutions that drive their success. Working with OEMs lets us get to the heart of what they need and create bespoke solutions that propel their success.

Get in touch to see some of the projects we are proud to have worked on and find out how we can help you with your next project.

Mining

With a dedicated technical application team Massload excels in weight applications for mining.

Our expertise covers vehicle weighing (above and underground), bin weighing, shaft sinking, galloway weighing, headframe sheave weighing, girder hoisting, belt tensioning, rope attachment sensing, ensuring precision and safety in challenging mining environments.

Oil & Gas

Our load cell solutions for oil and gas applications include gas desanding, proppant weighing, pipe laying, hoisting, wireline tension monitoring.

We also do custom design projects, such as this case study: Weigh Solution for Oil & Gas OEM: Natural Gas Desander

Naval

Our boat lifting & building applications cover lifting operations for dry docking and maintenance, and precise determination of a boat’s centre of gravity.

We also provide custom weighing solutions during the construction phase to ensure the boat’s centre of gravity is met as per design blueprints.

We’ve also designed a weigh application for cable ferries. This includes monitoring cable tension to prevent overload and damage to wire ropes.

Construction

Massload has rugged and reliable solutions for construction weighing applications, including lifting and vehicle check weighing.

In hydro dams our applications include sluice gate cable tension monitoring and overhead crane load sensing.

We also develop rugged and reliable, all weather solutions for process batching and on-board weighing of tanks, hoppers, silos and any other vessel weigh application.

Transportation and Logistics

Transport weighing applications come in many shapes and sizes. That’s why Massload has a rugged range of reliable solutions for above-ground and in-ground truck axle scale applications.

Get to know our load cell options for:

Truck Weighing

Traffic Enforcement Solutions

Other Load Cell Applications

- Material Handling & Crane Modernization – Custom load pin solutions for crane modernization applications including hook block, sheave load and secondary sheave load monitoring as well as for standard lifting solutions in material handling applications.

- Lifting & Hoisting – Industrial solutions for tension link weighing, load shackle weighing, dynamic wire rope tension monitoring, dead-end line tension monitoring, and hoist drum load monitoring.

- Vehicle Recovery – Wireless tension link load monitoring for safe, accident free lifting.

Technical Specifications

Each load cell we develop is designed with a specific use and industry in mind. This results in a wide array of available options, yet only a few might be the perfect match for your specific applications.

Understanding the performance you can expect from each type is the first step, and we are always available to assist you and your team in this regard.

Dimensions and Form Factors

Load measurement requirements vary across applications. That’s why we have load cells in all sizes, shapes and designs:

- Tension Links: Seen in lifting & hoisting applications, especially in cranes, winching systems, towing, load-lifting and hanging scale applications.

- Load Shackle: For under-pressure situations where load measurement is required in rigging and lifting applications, such as road rescue and towing, load lifting, boat lifting and line tension measurement.

- Single and Double-ended Shear Beams Load Cells: For industrial weighing systems or rigid mount applications like tank and hopper batch weighing, and vehicle weigh scales. Some types can meet legal-for-trade requirements.

- HCH Wagon Hitch Single Ended Shear Beam Load Cells: Specifically designed for railcar, grain car, and manure wagon weighing.

- S-type Load Cells: You’ll typically find these in applications requiring both tension and compression loading, such as tank and hopper weighing.

- CBL Tank Hopper Load Cells: The go-to choice for precise measurements in bulk material handling, such as in silos, tanks, and hoppers. This versatile, low-profile load cell is ideal for tank, hopper, and vessel weighing.

In addition to our standard range, we also offer Custom Load Cells, Custom Load Pins and Custom Tension Links.

Designed to your exact requirements, so no matter what your special requirement is, we have the load cell for you.

Connectivity Options

Whether your setup requires wired or wireless our load cells integrate seamlessly with your existing systems.

The same applies to data interaction; our load cells interface with various data logging systems making data collection and analysis easier for better operational efficiency.

Check out some of our wireless connectivity options for load cells:

Wireless Load Cells

Interconnectors, Interfaces and Hardware

Certifications and Compliance with Industry Standards

- Proudly Canadian: Our load cells are 100% made in Canada, more specifically in Saskatoon, SK, with the highest standards of quality and craftsmanship in mind.

- VCAP Certification: Massload Technologies is Canada’s only load cell manufacturing facility certified under the Verified Conformity Assessment Program (VCAP).

- Extended Warranty: We back our products with confidence, offering an industry-leading 2+ year warranty, ensuring peace of mind and reliability in your investment.

- Precision Calibrated: Our load cells, when meticulously calibrated through a multi-point system, ensure an exceptional accuracy range between 0.1% to 0.2%.

Choose Massload Technologies for Load Cell Excellence in Canada and the United States

We are confident we have a perfect load cell for every customer and industrial application.

Contact Us online or Request a Solution, and let us find the solution that your company needs.

Frequently Asked Questions About Load Cells

What Factors Can Affect the Accuracy of Load Cells?

- Environmental Conditions: Temperature, humidity, and vibration can introduce errors.

- Mounting and Installation: Uneven load distribution, misalignment, and excessive torque can lead to inaccuracies.

- Overload Protection: Exceeding rated capacity can cause permanent damage and accuracy loss.

- Signal Conditioners and Amplification: High-quality devices are essential to produce amplified signals, minimizing noise and interference.

- Calibration and Maintenance: Regular calibration and maintenance are crucial for sustained accuracy.

What Are the Common Specifications that Help Define Load Cell Performance?

-

- Non-linearity: Deviation from a straight line over the measurement range.

- Hysteresis: Difference in readings for increasing and decreasing loads.

- Repeatability: Ability to reproduce the same output under the same conditions.

- Creep: Gradual change in output when a constant load is applied.

- Temperature Effects: Deviation in readings due to temperature changes.

- Zero Balance: Output reading when no load is applied.

Why Is Calibration And Regular Maintenance Important For Load Cells?

Calibration ensures the load cell’s output matches the reference standard. Maintenance (cleaning and inspection) helps you identify and correct deviations so accuracy and reliability last as long as possible.

How Do You Protect Load Cells From Environmental Factors?

Load cells are critical for force and weight measurement and need to be protected from environmental factors to perform and last. Here are ways to protect load cells from harsh conditions:

- Environmental Resistance: Load cells can be designed with specific materials and coatings to withstand harsh environmental conditions. For example, Massload load cells are manufactured using material nickel plated 4340 Alloy Steel or 17-4PH Stainless Steel and heat treatment creating protective layers to resist corrosion and damage from moisture, dust, and chemicals.

- Sealed and Enclosed Designs: To prevent ingress of dust, moisture, and other contaminants, load cells can be sealed or enclosed. Hermetically sealed load cells offer the highest level of protection, with welded covers and gaskets ensuring no external factors can affect the internal components.

- Protective Coatings: Applying protective coatings such as epoxy or other corrosion-resistant materials can enhance the durability of load cells. These coatings act as a barrier against corrosive elements, extending the lifespan of the load cells in challenging environments.

- Temperature Compensation: Load cells can be equipped with temperature compensation features to minimize the effects of temperature fluctuations. This is particularly important in environments with extreme temperature variations, ensuring consistent accuracy despite temperature changes.

- Proper Housing: Installing load cells in protective housings or enclosures can shield them from physical damage and environmental stress. For instance, load cells used in construction or industrial settings can be housed in robust casings that protect against impact, vibration, and exposure to the elements.

- Regular Maintenance and Inspection: Routine maintenance and inspection are vital to ensure load cells remain in optimal condition. Regularly checking for signs of wear, corrosion, or damage allows for timely interventions and replacements, preventing potential failures due to environmental exposure.

- Custom Designs for Specific Applications: Custom-designed load cells tailored to specific applications can offer enhanced protection and performance. For example, load cells used in marine environments can be designed with special considerations for saltwater corrosion, while those used in explosive atmospheres can be made intrinsically safe.

- Calibration and Adjustment: Regular calibration and adjustment help maintain load cell accuracy. Environmental factors can cause drifts in measurements, and routine calibration ensures any deviations are corrected, maintaining the reliability of the load cells.

By implementing these protective measures, load cells can operate reliably and accurately in industrial, mining and outdoor environments. Load cells need to be designed and maintained with environmental protection in mind to last long and accurately.

Can Load Cells Handle Both Tension And Compression Forces?

Yes, some load cells like S-type load cells can measure both tension and compression forces.