Texas Agriculture and Industrial Weighing Solutions

Texas’s agricultural sector presents unique measurement challenges that standard commercial scales struggle to address:

- Environmental Exposure: Outdoor operations exposed to temperature extremes, precipitation, dust, and UV radiation that rapidly degrade inadequately protected systems.

- Mobile Applications: Portable weighing requirements for field operations where conventional fixed scales prove impractical or prohibitively expensive.

- Variable Materials: Measurement needs spanning livestock with continuous movement to bulk commodities with shifting density and moisture content that affect weight determination.

- Seasonal Intensity: Operational patterns with periodic high-volume usage followed by extended idle periods that create unique reliability challenges for weighing equipment.

Massload’s agricultural scales incorporate specialized protection systems, motion compensation algorithms, and rugged construction methods that maintain accuracy despite these challenging conditions.

Transportation and Logistics in Texas

As a major transportation hub connecting international shipping with national distribution, Texas requires specialized weighing technology for operational efficiency:

- Vehicle Weighing Challenges: High-volume truck traffic requiring efficient weight verification without sacrificing accuracy or compliance documentation.

- Environmental Factors: Outdoor scale installations exposed to Texas’s weather extremes from coastal humidity to inland temperature variations that affect both mechanical systems and electronics.

- Regulatory Requirements: Compliance with specific weight limitations on highways and bridges, requiring documented verification to prevent violations and associated penalties.

- Operational Efficiency Demands: Weighing systems that balance thorough verification with rapid processing to maintain logistics throughput in high-volume operations.

Massload’s transportation scales combine mechanical durability with efficient operation, delivering accurate weight verification while minimizing processing time—a critical balance for Texas’s extensive logistics operations where both compliance and throughput directly impact operational profitability.

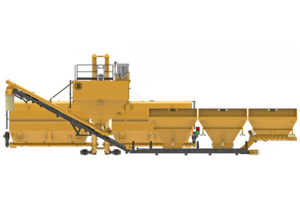

Manufacturing and Construction Industries

Texas’s diverse manufacturing and construction sectors present measurement challenges spanning micro-precision to massive capacity:

- Process Control Requirements: Real-time weight monitoring for OEMs for batching, blending, and formulation where measurement accuracy directly impacts product quality and consistency.

- Material Management: Inventory tracking throughout production processes, from raw material receiving through intermediate storage to finished product shipment.

- Quality Verification: Weight-based inspection systems that identify non-conforming products or components through precise measurement rather than visual inspection.

- Equipment Protection: Load monitoring that prevents overloading of lifting systems, material handling equipment, and structural elements where excess weight could create safety hazards or equipment damage.

These applications demand weighing systems engineered for specific operational requirements rather than general-purpose scales, with mechanical designs, protection systems, and signal processing optimized for particular usage scenarios and environmental conditions.

Mining Industry in Texas

Texas’s diverse mining operations present specialized weighing challenges that demand robust, high-precision measurement solutions:

- Extreme Operating Environments: From limestone quarries to sulfur mines, Texas mining operations expose weighing equipment to harsh conditions including abrasive dust, caustic materials, and temperature extremes that quickly degrade standard commercial systems.

- Safety-Critical Applications: Mining operations rely on accurate weight measurement for critical safety applications including hoisting systems, underground support structures, and material transfer points where measurement failures could create hazardous conditions.

- Production Efficiency Requirements: Accurate weight data directly impacts processing efficiency, material reconciliation, and inventory management throughout mining operations, where even small measurement errors can significantly affect operational profitability.

- Mobile Equipment Integration: Texas mining operations utilize specialized equipment requiring onboard weighing systems that maintain accuracy despite continuous motion, vibration, and shock loading during normal operation.

Massload’s mining scales are engineered specifically for these demanding conditions, with reinforced structures, enhanced environmental protection, and specialized mounting systems that maintain measurement accuracy despite the challenging conditions of mining operations throughout Texas.