In tanks, hoppers, silos and large industrial platforms, several load cells share the job of measuring weight.

When everything is set up and calibrated properly, those cells distribute the load evenly and the system performs like clockwork.

But when that balance gets knocked out of whack, due to installation, foundation movement, vibration, thermal expansion or mechanical binding, a load cell can fail.

This phenomenon, which is one of the most common load cell problems that causes cell failures, is called non-uniform loading. It is easy to miss but can be extremely costly if left undetected.

What Causes Non-Uniform Loading and How It Affects Your System

Non-uniform loading occurs when the weight isn’t evenly distributed across all load cells in a system. These imbalances can creep in from all sorts of places:

- A tank or hopper that’s not sitting on its feet properly

- Mechanical binding or friction at mounts where the cells sit

- Thermal expansion causing the frame to distort and go out of shape

- Foundation settling or the floor moving around

- A pipe connection pulling laterally on the structure

- Over-tight or misaligned mounting hardware

- Vibration or shock-loading conditions

When one load cell is carrying more stress than the others, it doesn’t just give a dodgy reading, it also starts to age at a faster rate.

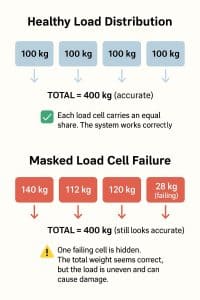

And that sets in motion a chain of events that operators usually don’t even see happening: The other load cells start to compensate, effectively masking the problem.

How Multi-Load Cell Systems Quietly Hide Load Cell Failure

Most tank and hopper systems use a summing junction box that combines the signals from multiple load cells into one total weight reading. Now, have a look at what happens when one cell starts to drift or weaken:

One cell is now performing far below its means and the others are working way too hard.

This is why non-uniform loading is a sneaky failure mode. And it doesn’t usually end quietly.

Over time:

- The overstressed cells start to get tired faster.

- Signal drift speeds up.

- Calibration becomes harder to keep track of.

- The structure itself may start to experience uneven forces.

Eventually, another load cell gives way and that’s when operators finally notice but by then the problem is no longer small.

The Risk Isn’t Just Bad Data, It’s Operational Safety

When a load cell system is allowed to run in imbalance for too long, the consequences can include:

| Risk | Impact |

| Sudden load cell failure | Downtime and emergency replacement |

| Hopper/tank instability | Structural stress or tipping risk |

| Batch inconsistency | Lost product or quality failures |

| Crane/hoist overload conditions | Safety hazards for personnel |

| Increased maintenance cost | Replacing multiple cells instead of one |

If your job involves:

- Bulk material dosing

- Batching

- Vehicle loading/unloading

- Lifting or hoisting

Precision isn’t just about accuracy, it’s about safety and predictability.

How to Detect Non-Uniform Loading (Before It Becomes a Breakdown)

1. Perform Corner or Sectional Load Testing

Test each load cell individually under partial loads.

If one corner is reading way off or way below, you’ve got an imbalance.

2. Inspect Mounting Hardware

Look for:

- Bent plates

- Worn pivot points

- Corrosion

- Over-tightened bolts

Even small mechanical friction can distort the load.

3. Check For Piping Or Conduit Pulling On The Structure

A stiff pipe connection can ‘steal’ load from a cell and this is one of the most common hidden causes of dodgy readings.

4. Schedule Regular Calibration Under Real Load

Calibrating just at zero load can hide an imbalance. Multipoint calibration and tests near operational weight will give you a more accurate picture.

5. Use A Junction Box With Proper Trimming And Isolation

Trimming ensures the load is shared properly. Isolation makes it easier to spot a weak cell during troubleshooting.

How Massload Designs to Reduce Non-Uniform Loading Risk

Massload systems are built with the real world in mind, not just some lab where everything goes according to plan.

We focus on a few key things to make sure you can rely on them in pretty much any environment:

- Mounting kits that can take a bit of movement, without letting things get jammed up;

- Load cells that are protected from the elements and actually stay accurate;

- Hardware that’s been engineered to withstand shock and all the vibrations that come with it;

- Steel that’s made the tough way, in Canada – built to last in extreme conditions;

- Calibration and service support that’s good to go right from the start.

Because let’s face it, the real world is rarely, if ever, perfectly level, still or predictable, and your weighing system shouldn’t be at risk of failing just because life decides to get a little more interesting.

Protect Your System and Spot Hidden Load Cell Failures Before They Escalate

Non-uniform loading is usually quiet, until it finally isn’t. A system can look spot-on, only for drift to start creeping in and eventually lead to load cell failure.

When the load isn’t being shared evenly across a multi-load cell system, the failing cell can be sneaking up on you.

The other cells will do their best to compensate and keep the weight reading as close to accurate as possible and that means you might not even notice one or more of the cells is on the way out.

It’s only when this all comes crashing down that the issue becomes a major problem.

Which is why proactively checking on the system, calibrating it and getting the alignment right is just as important as the load cell itself. It’s not just about measuring weight, it’s about paying attention to what your system is telling you, even when it’s trying to whisper a warning in your ear.

Stay ahead of load cell issues and keep your operations running smoothly by contacting Massload Technologies today.