1100 Double-Ended Shear Beam Load Cell Transducer

This load cell transducer is designed for rigid mount and very rugged applications. A key feature of this load cell is that the bolt holes are located at the bottom of the load cell which allows it to be mounted from a base beneath the load cell. This makes it an ideal sensor for onboard weighing and any other situation where dynamic loads may be applied. Because of this design, it is the standard load cell for Massload’s truck axle pad scales and weigh-in-motion scales.

Highlights

- High quality Canadian-made load cell transducer manufactured in Canada’s only VCAP (Verified Conformity Assessment Program) certified load cell manufacturing facility

- Super-duty precision double-beam load cell transducer for use in rugged, industrial, non legal-for-trade applications

- Used in rigid mount truck scale applications such as Massload truck axle pad scales, truck trailer scales, weigh-in-motion scales, and on-board weighing

- Center loaded

- 4340 Alloy Steel

- 2 year warranty

Product Details

1100 Double-Ended Shear Beam Load Cell Transducer

The 1100 Double-Ended Shear Beam Load Cell Transducer is purpose-built for rugged and demanding industrial applications, where precision, durability, and resilience are critical.

This distinctive characteristic makes it an optimal choice for onboard weighing systems, offering precise measurements even under dynamic load conditions.

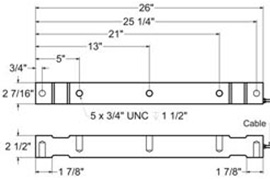

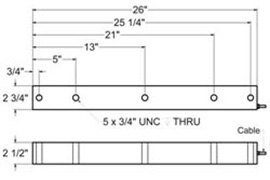

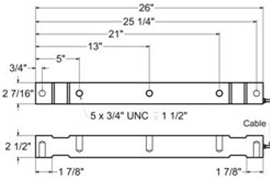

Images

PRODUCT SPECIFICATIONS

| Capacities (pounds) | 25,000 lbs and 50,000 lbs load cell capacities |

|---|---|

| Safe Overload | 150% full scale safe overload |

| Ultimate Overload | 300% full scale ultimate overload |

| Full Scale Output | 2mV/V +/- 0.25% FS |

| Maximum Excitation | 15 volts DC |

| Operating Temp | -40°C to +80°C |

| Compensated Temp | -10°C to +40°C |

| Sealing Standard | IP-67 protected against high pressure jets of water |

| Non Linearity | 25K AXL +/-0.05% FS |

| Material | 4140 / 4340 High Strength Alloy Steel |

| Protective Coating | Electro-less nickel – industrial high phosphorous, corrosion and chip resistant |

| Bridge Resistance | 700 Ohm |