Weighing systems serve California mining operations across the entire production chain, from extraction through processing to final product shipment. The following applications represent the core measurement points where accuracy directly impacts operational efficiency, safety, and commercial outcomes. Detailed equipment specifications appear in the Product Capabilities section.

Haul Truck & Vehicle Weighing

Onboard Payload Systems: Real-time payload measurement integrated into haul trucks provides operators with immediate feedback on current load status, enabling target loading without overloading. Modern systems integrate with fleet management software for production tracking, maintenance scheduling based on actual payload history, and operational optimization. These systems must maintain accuracy despite continuous shock loading, vibration from haul roads, and temperature extremes that would rapidly degrade conventional weighing technology.

Truck Axle Scale Stations: Permanent and portable axle scales and load scanners provide production verification, support commercial transactions, and enable calibration verification for onboard systems. Mining-grade installations maintain calibration stability despite continuous heavy traffic and harsh environmental exposure, delivering accurate measurement for inventory control, billing verification, and regulatory compliance.

Loader Bucket Scales: Dynamic weighing during loading operations enables accurate truck loading without requiring trucks to stop at a scale. Operators receive real-time bucket weight data, optimizing loading efficiency while preventing overloading. These systems must function reliably despite the continuous shock, vibration, and dust exposure characteristic of loading operations.

Conveyor & Belt Scales

In-Motion Belt Weighing: Continuous tonnage rate and totalization for overland conveyors, plant feed systems, and product conveyors. Belt scales provide real-time production data for process control and production reporting, but only if they maintain accuracy despite dust accumulation, belt tension variation, and structural vibration that typically degrades conventional systems.

Feeder Weighing: Apron feeder and vibrating feeder monitoring provides crusher feed control data critical for optimizing crusher throughput and preventing overload conditions. Feeder scales must handle the challenging environment directly upstream of primary crushing.

Calibration Systems: Test weight and material run calibration capability for belt scale verification. Maintaining documented calibration is essential for production reporting credibility and commercial transactions based on belt scale totals.

Hopper, Bin & Stockpile Weighing

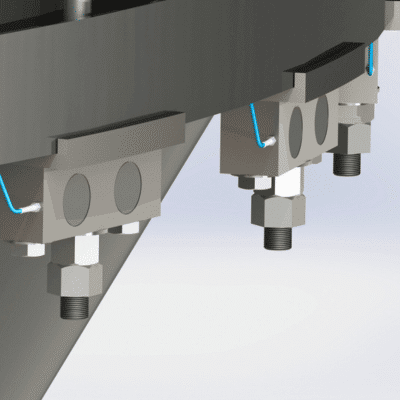

Surge Bin Monitoring: Continuous inventory measurement for ROM bins, crusher feed hoppers, and process surge capacity. Real-time level monitoring enables process optimization and prevents both overfilling and running-empty conditions that disrupt production flow.

Silo & Tank Weighing: Reagent tanks, grinding media storage, and product bins benefit from continuous weight-based monitoring that’s more accurate than level sensing alone. Consumption monitoring supports inventory management and reorder planning.

Stockpile Inventory: Weigh module systems provide more accurate stockpile inventory than volume-based estimation, supporting material accounting and inventory management.

Hoist & Crane Monitoring

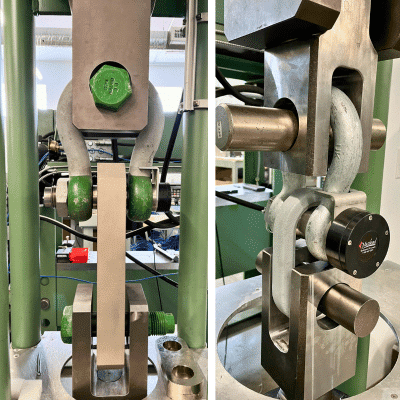

Skip & Cage Monitoring: Safety-critical load monitoring for underground mine hoists requires exceptional indicator reliability and accuracy. Overload protection prevents conditions that could damage equipment or endanger personnel. These systems operate in challenging underground environments combining moisture, dust, space constraints, and zero tolerance for failure.

Rope Tension: Continuous monitoring of hoist ropes and balance ropes supports maintenance prediction and safety verification. Tension trending can identify rope degradation before it becomes critical.

Crane & Rigging: Load verification for maintenance cranes, mobile cranes, and critical lifts during construction and maintenance operations. Mining environments require crane scales that function reliably despite dust, temperature extremes, and intermittent use patterns.

Aggregate & Construction Materials

Truck Scales: Aggregate sales depend on accurate, documented weighing for commercial transactions. Mining-grade truck scales maintain calibration despite continuous heavy traffic and outdoor environmental exposure characteristic of aggregate operations.

Loader Scales: Bucket weighing for customer loading and inventory tracking enables efficient operations without dedicated truck scales at every loading point.

Batch Plant Integration: Weighing for concrete and asphalt batch operations requires accuracy that directly impacts product quality, with systems that integrate with batch control infrastructure.